Company

Profile

At the forefront of gamma irradiation services, Pinnacle Therapeutics distinguishes itself through an unwavering dedication to precision, excellence, and cutting-edge innovation along with a customer-centric approach.

Boasting state-of-the-art facilities and a team of seasoned experts, Pinnacle guarantees meticulous care in the irradiation process, meticulously adhering to industry standards and regulatory mandates.

Choose your industry

Reduce Microbial Load, Enhance Shelf Life and Reduce Export Rejects: Organizations that require the use of food irradiation can rely on Pinnacle's broad-spectrum capabilities to meet more than 500 product types across thousands of facilities worldwide with the most comprehensive portfolio of advanced irradiation services.

Gamma irradiation is a reliable and versatile method for sterilizing a wide variety of products. It has been widely adopted in various industries such as medical, pharmaceutical, food, and cosmetic among others. Gamma irradiation's ability to penetrate deep into objects ensures effective sterilization without damaging the product.

Select your industry to view information relevant to your products.

Shyam Kadakia, MD

Vision

Our vision is to stand as the undisputed epitome in irradiation servicing.

We strive to lead the industry by setting unparalleled standards in precision, safety, and innovation.

As the go-to choice for businesses seeking sterilization excellence, we envision a future where our commitment to cutting-edge technology and unwavering service transforms industries.

Mission

At Pinnacle Therapeutics, we envision a world where our technical prowess and unwavering commitment eliminate bacterial threats from essential human commodities.

From agricultural to medical products, our dedication to integrity and technical excellence transcends borders, forging a path toward a global healthcare landscape.

Our mission is to play a pivotal role in fostering a healthy society and, in turn, a healthier world. We strive to make a lasting impact on the well-being of individuals worldwide by ensuring the safety and purity of every human intake under our care.

About Us

At Pinnacle Therapeutics, we lead in gamma irradiation services, employing cutting-edge technology and a skilled team. With years of industry expertise, we dedicate ourselves to providing top-notch sterilization solutions for diverse sectors, including spices, medical devices, and pet food.

Our goal: exceed expectations through reliable, efficient, and safe services.

Partner with us and elevate your experience with the pinnacle of gamma irradiation.

Our Facilities

The main Pinnacle Therapeutics gamma irradiation facility is in the industrial park at Sanand, Gujarat. Our proximity to Kandla, national railways network, several MNCs ensures that we are able to cater to our customers in the most efficient and updated way possible.

Our cutting-edge facilities are equipped with advanced gamma irradiation equipment, ensuring that we can meet the most demanding sterilization requirements. We prioritize maintaining a clean and controlled environment, adhering to international standards to guarantee the safety and efficacy of our processes.

Certifications

Pinnacle Therapeutics is committed to maintaining the highest level of quality and compliance. We have obtained various certifications that validate our dedication to upholding industry standards.

Our

Services

01

02

Gamma Irradiation

Employ high-energy gamma rays to sterilize and decontaminate various products, ensuring enhanced safety, extended shelf life, and compliance with rigorous industry standards.

Dose Audit

As per ISO 11137-2 -Sterilization of Healthcare Products the client is supposed to regularly carry our dose audit for sterilization via gamma irradiation. We provide such dose audit at periodic intervals for our clients

Our

Additional Services

01

Validation

02

Dose Mapping

03

Logistics

Client Testimonials

Our commitment to quality and safety transforms industries. Explore the testimonials from diverse sectors—pharmaceuticals, agro-products, spices, and medical devices. Join the ranks of satisfied clients who have entrusted us to elevate their standards.

Pharmaceutical

“Pinnacle ensures our eye drops meet the highest sterilization standards and reduce contamination risks.”

Masala Manufacturer and Exporter

“Pinnacle's gamma irradiation preserves the spice essence flawlessly. On time delivery and excellent customer support makes them our preferred irradiation partners"

Isabgol Producer

"Pinnacle's irradiation ensures pure and safe Isabgol material and has helped us export confidently.”

Medical Implantation Manufacturer

"Pinnacle's precision ensures the safety of our medical implants."

Knowledge Centre

In our Knowledge Centre, we aim to provide valuable resources and educational materials related to gamma irradiation and sterilization.

Our knowledge center includes articles, case studies, industry insights, and expert advice. Whether you are looking to learn more about the benefits of gamma irradiation or seeking solutions to specific sterilization challenges, our Knowledge Centre is an excellent resource for you.

What is gamma irradiation?

Gamma irradiation, a powerful technology rooted in the principles of nuclear physics, has emerged as a key player in various industries, ensuring safety, quality, and preservation of products. Let's delve into what gamma irradiation is, and explore its diverse applications, particularly in the spice, medical, pet food, and dry food industries.

Gamma irradiation is a process that involves exposing products to gamma rays, which are high-energy photons emitted by a radioactive source, usually Cobalt-60 or Cesium-137. These rays effectively penetrate materials, disrupting the DNA of microorganisms and preventing their growth and reproduction. This method is widely employed for its ability to sterilize, decontaminate, and extend the shelf life of various products.

Gamma Irradiation for Spices

In the spice industry, where maintaining the purity and quality of products is paramount, gamma irradiation plays a crucial role. This process effectively eliminates bacteria, molds, and pathogens present in spices, ensuring that the irradiated product is not only safe for consumption but also retains its flavor and aroma. Gamma irradiation is a preferred method for treating spices, as it doesn't alter the chemical composition or sensory attributes.

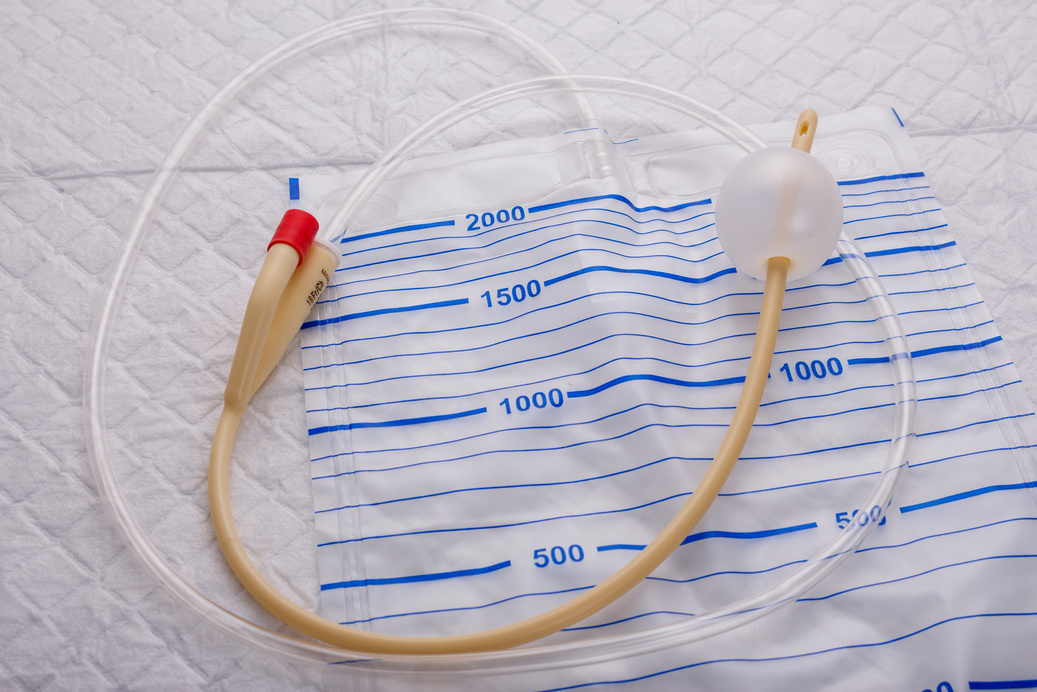

Gamma Irradiation for Medical Industry

Gamma irradiation is extensively used in the medical field for sterilizing medical devices, pharmaceuticals, and biological tissues. The process ensures the elimination of harmful microorganisms, making medical products safe for use and reducing the risk of infections. This is particularly crucial in areas like surgery, where the absence of microbial contamination is non-negotiable.

Gamma Irradiation for Pet Foods

In the pet food industry, gamma irradiation serves as a reliable method for eliminating harmful bacteria and parasites that may be present in raw materials or finished products. This ensures the safety of pet food, protecting both the pets and their owners from potential health risks. Additionally, gamma irradiation helps in maintaining the nutritional value of pet food by preventing the growth of mold and preserving essential nutrients.

Gamma Irradiation for Dry Foods

Gamma irradiation is employed in the dry food industry to extend the shelf life of products such as herbs, dehydrated onion and garlic, spices, grains, and dried fruits. By eliminating pests and pathogens, this method ensures the integrity of the food, reducing the need for chemical preservatives.

Consumers can enjoy safe and high-quality dry food products with confidence, enhancing manufacturers’ capability.

Cosmetics and Personal Care Products

Cosmetics and personal care products such as shampoos, lotions, creams, and makeup have a shorter shelf life due to their organic components.

Gamma irradiation extends the shelf life of these products, making it appealing for companies that want to serve customers for longer periods. Gamma irradiation is preferred because it's a non-invasive process that doesn't alter any of the product's key attributes.

Other Products

Gamma irradiation can be used in products such as electronics for the sterilization of component parts and products that undergo antibiotics testing.

Enhancing Safety and Quality with Gamma Irradiation for Laboratory Disposables

For laboratory disposables the choice of sterilization method is pivotal. Gamma irradiation emerges as the optimal solution, offering distinct advantages over alternative methods such as Ethylene Oxide (ETO).

Why Gamma Irradiation for Laboratory Disposables:

- Material Compatibility:

- Gamma irradiation ensures gentle sterilization, preserving the integrity of materials crucial for laboratory disposables.

- Residue-Free Sterilization:

- Unlike ETO, gamma irradiation leaves no residues behind, eliminating concerns about potential chemical residuals in laboratory samples.

- Immediate Product Use:

- Sterilized laboratory disposables are ready for immediate use after gamma irradiation, enhancing efficiency in testing workflows.

- Broad Material Applicability:

- Gamma irradiation is compatible with a diverse range of materials used in laboratory disposables, ensuring flexibility and versatility.

- Environmental Friendliness:

- Gamma irradiation aligns with eco-conscious practices, providing a sustainable and environmentally friendly sterilization solution.

- Global Regulatory Compliance:

- With increasing regulatory restrictions on ETO, gamma irradiation offers a globally accepted and compliant sterilization method for laboratory disposables.

In summary, gamma irradiation stands as the preferred choice for laboratory disposables, particularly blood test tube collection units, ensuring uncompromised safety, quality, and regulatory adherence. Choose the gold standard in sterilization with Pinnacle Therapeutics.

Benefits of Gamma Irradiation

Gamma irradiation offers numerous benefits for clients seeking sterilization solutions. Some of the key advantages include:

1.Consistent and Reliable Sterilization

2.Non-Destructive Process

3.Versatility

4.High Penetration Capacity

5.Extended Shelf Life

6.No Residue

7.Compliance with Regulatory Standards

8.Traceability

9.Cost-Effective

10.Environmental Friendliness

By choosing gamma irradiation services from Pinnacle Therapeutics, clients can benefit from all these advantages, ensuring their products are safely and effectively sterilized for the protection of end-users.

Contact us today to discuss your sterilization needs and discover the Pinnacle difference.

Processing your Material

1st Stop

2nd Stop

Material arrives at our facility. It is unloaded, cross checked and kept at our facility.

Material details are carefully verified. The packaging is checked and plant head conducts final inspection before processing.

3rd Stop

4th Stop

The material is loaded on the machine carefully to undergo irradiation processing, as per the required dosage.

The material is unloaded, labelled, certified and after corporate office clearance, is loaded back into the truck to reach its final destination - 100% irradiated.

Mailing Address

Phone Number

+91-9725002284

Email Address

info@pinnaclesterilization.com

Contact Form

Plant Address

Mailing Address

Phone Number

Email Address